The Brief

The brief was simple; we set out to find out the most eco-friendly way to package our coffee. This has always been, and remains, the most important factor for us. A seemingly central theme in the Speciality Coffee scene is sustainability and making our footprints as small as possible. This is something I've always personally believed in too, so there was no doubt in my mind that this process needed to put the environment first.

Secondary to this, the form factor should make it possible for one or two 250g bags to be delivered within the Large Letter size of parcel. This means letterbox friendly packaging and gives us the ability to reduce our (and your) postage costs, the size of our packaging and therefore reduce our carbon creation even further.

Finally, it had to look good and not cost too much (standard business and marketing stuff really).

The Challenge

Paper is better than plastic, right? Turns out there is a whole lot of disinformation (deliberately intended to mislead) on this subject and it’s something of a minefield. But since we set out with a goal to find out the most eco-friendly way to package our coffee, we needed to make as much sense of this as possible.

There are several materials that we considered from various manufacturers;

- Paper (virgin & recycled)

- Recyclable Plastic

- Compostable Plastic

- Eco materials like seaweeds etc.

Each material should be considered for the following criteria;

- Performance, ability to protect and store the coffee

- Carbon cost to create

- Recyclability ease, including carbon cost

- Logistics costs / carbon

- Monetary cost per unit / minimum order quantities

It immediately becomes apparent that the scale of the task, if undertaken correctly, was going to be huge.

The Compromise

Paper

I think that it’s a fairly widely held belief that paper seems to have fairly good eco-credentials. This was indeed my view before undertaking this project too. However, it turns out that there’s plenty of reading material that would argue and tries to re-position paper as a villain.

There’s certainly merit to some points here, such as the harmful use of chemicals in bleaching of paper and the huge costs (and more chemicals) involved in recycling paper. However, it’s hard to come across real numbers for carbon creation and to know the real impact of isolated chemical use in its production. After all, it’s quite possible to use un-bleached paper, too.

My feeling was that there’s a good amount of plastic-propaganda (spurious studies by the plastic industry) there to confuse the matter, and I felt that on balance, paper was still more renewable.

I am also allowing for the deforestation concerns linked to paper here, which I believe can be more properly controlled more easily than with fossil fuel usage associated with plastics.

However, despite all of this I found that paper was not going to be suitable.

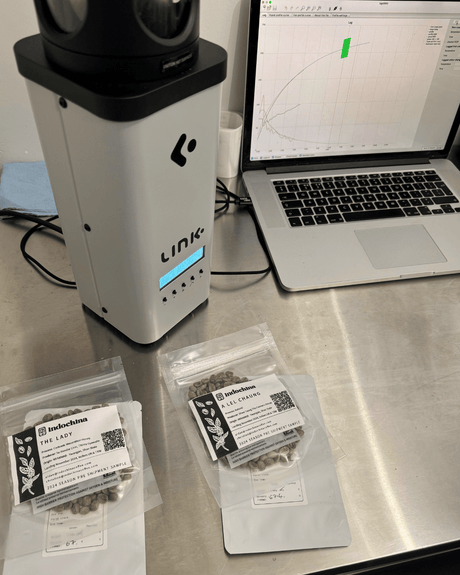

Although I sourced and (repeatedly) tested paper coffee pouches, there were two problems that were insurmountable, for now at least…

The valve; required to release the CO2 that coffee emits after roasting is only available as a plastic part. I considered this unacceptable since people would not likely separate the valve before disposing of the bag which would therefore prevent the paper from being successfully recycled. I also tried without a value altogether, this had the effect of inflating the bag, but also degrading the beans as they were ‘soaked’ in a CO2 atmosphere.

The taste; some of the paper bags we tried imparted an unpleasant taste on the coffee.

Plastic

Plastics are generally considered bad. Being derived from fossil fuels, not universally recycled and taking up to 500 years to decompose are all bad things.

So why might a sustainable coffee company choose to use plastic anyway?

This question had me stumped before I started trying to search for better alternatives, but following my experiences with paper, I began to understand some more.

There are several grades of plastic available for making coffee pouches; non-recyclable ones like mylar, recyclable options like LDPE, and then other compostable types.

The aforementioned valve which allows CO2 to escape is not always made of the same plastic as the bag itself. Again, I felt those options were unacceptable due to the likelihood that people would fail to separate the valves from the bag.

I considered two types seriously; LDPE and compostable.

LDPE is recyclable with other plastic bags at supermarkets, whilst this is not ideal, it is at least possible to recycle them in this way.

Compostable bags are potentially a great idea. However, in practise there are very few household refuse processors in the UK that would actually process them with other compostable matter, such as taking them with the food waste bins each week. In reality these bags are separated and sent to landfill. This was really a disappointing truth in my research.

Other materials

Looking around at some of the amazing companies in the Speciality Coffee space, there is no shortage of innovation when it comes to packaging. Glass, aluminium, organic materials like seaweed and plastic bottles are all possible as proven by many brands hoping to find point of differentiation.

The reality of these materials is that they come with several compromises over the commonly used bags that still dominate the space;

- Cost typically much higher or have high minimum order quantities

- Shape not always suitable for shipping

- Fragility, eg glass

- Lack of valves

Now, it’s certainly not impossible to imagine using a nice aluminium bottle or glass receptacle to showcase our finest beans. But to replace all of our packaging? That would probably not be practical or cost-effective.

For limited release series however, these options do have merit, watch this space…

The Result

After a lot of research and plenty of trial and error, there were two viable options to chose from;

- LDPE mono-material bags

- Paper bags without a valve

The long-term testing we did with paper, however, just wasn’t able to pass our quality standards. A combination of the bag swelling and the degradation in taste meant that I had to park the idea of paper.

Switching focus to LDPE bags, we found a carbon-neutral manufacturer that is able to make fully-recyclable mono-material bags that can be recycled at supermarkets, the same way carrier bags are recycled.

Obviously this is a compromise, are you really going to take your empty coffee bags to be recycled at your supermarket? Do you even go to the supermarket any more? I certainly hope so.

One major benefit of this process is the new bag size format. We can now fit our 250g bags into Royal Mail’s Large Letter size packaging. This allows us to introduce some lower cost shipping options, we’ll announce this separately once we’ve ironed out the details. Hooray!

The Future

The process of evolving our packaging actually started at the formation of the company, and it will likely continue throughout the company’s life. Like everything in coffee, it will never be ‘perfect’.

Whilst I’m confident that I’ve done the best I can with the materials and options that are available now, new innovations are happening all the time.

If an all-paper, valved bag to be invented tomorrow then we would almost certainly adopt it, but for now I’m satisfied that we’re doing the best we can.